Table of Contents

ToggleChoose drop wire clamps from 5 aspects

Are you troubled by not knowing how to choose the right drop wire clamps for your project?

They have a wide range of uses: They can be used to fix and support electrical power cables, and can be used with house hooks and span clamps to secure fiber optic cables. This article will help you get clear on how to choose a suitable drop wire clamp so that you are no longer confused.

1. Application Areas:

- Communications areas: These wire clamps are used to secure fiber optic cables to buildings or utility poles. Ensure the stability and safety of the cables.

- Electrical power areas: They are used to support single or dual telephone drop lines. Usually fixed on street light poles.

- Construction areas: Used to fix the steel wire rope on the building and share the tension of the steel wire rope.

2. Installation form:

- Compression: Uses compression between the clamps and the wedges to secure the cables.

- Wire wrap: Wrap the cables around the drop wire clamps to secure.

3. Design Features:

- Open cable groove: You just need to put the cable into the cable groove of the drop clips.

- Detachable: Most of the drop wire clamps are detachable and reusable. It is easy for you to install and maintain.

4. Advantages:

- Transmission: Wire clamps secure cables without affecting electrical or signal transmission.

- Support and relief: They are used to support the weight of the cable and share the tension at the connection point (Such as buildings and telephone poles).

- Load Capacity: Drop wire clamps have the largest load capacity of 500~700.

5. Materials:

- 304 stainless steel: Moderate performance. They have good corrosion resistance, high strength, and moderate cost.

- 316 stainless steel: Wire clamps have the best corrosion resistance, high strength and wear resistance, long service life, and high cost.

- Aluminum Alloy: Good corrosion resistance, light weight, cheap, and economical.

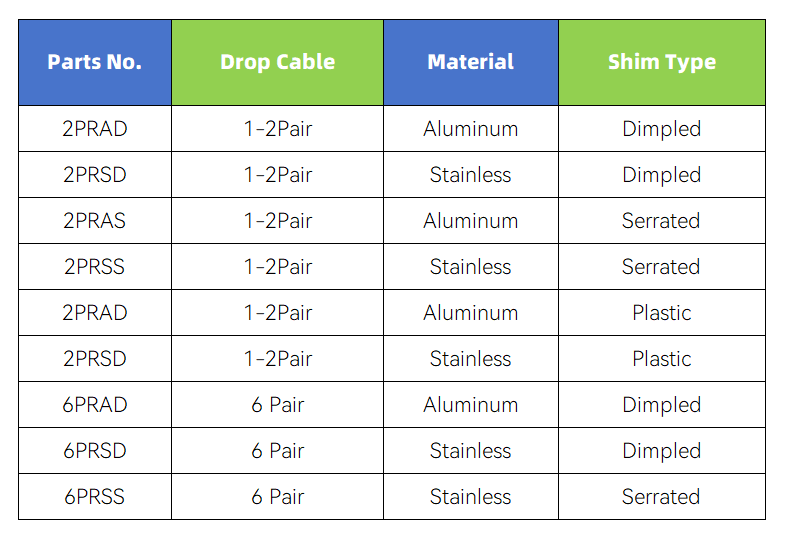

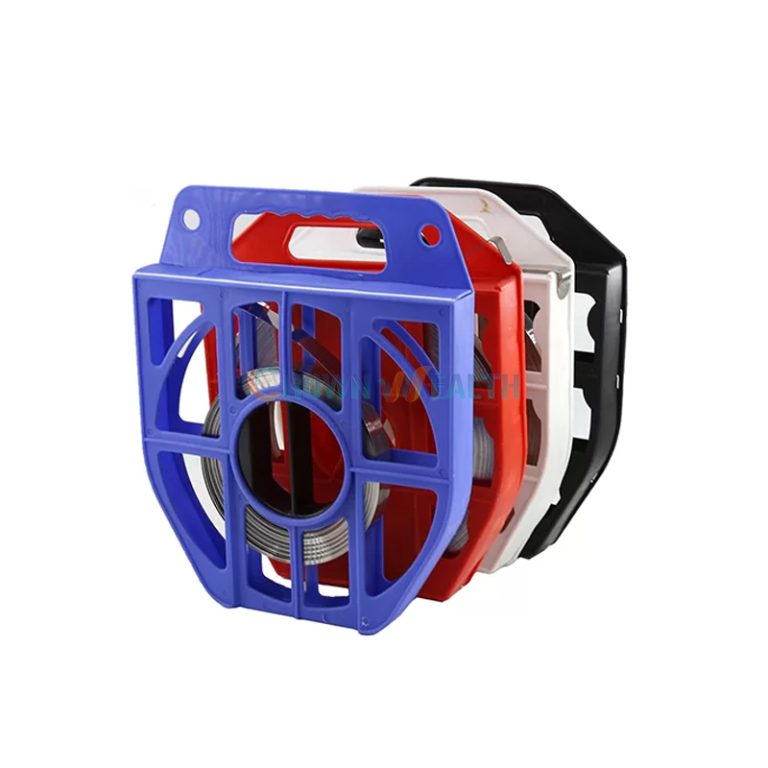

Specifications of drop wire clamps

Different cable sizes require different metal clamp sizes. It is important to understand their specifications and choose the most suitable clamps to apply your project.

What should you pay attention to when installing the drop wire clamps?

According to statistics, there are hundreds of safety accidents caused by cable breakage due to damage to the drop clamps, so it is important to understand the precautions when installing them.

- Choose the right size drop wire clamps.

- Determine the cable path and stable installation location.

- Insert successively rubber/stainless steel gaskets and wedges as required.

- After installation, check whether the drop cable clamps are loose or deformed.

- Clean the drop wire clamps regularly to remove dust and dirt from the surface. Apply anti-rust oil to prevent rust.

The development trend of drop cable clamps

- Lightweight: Aluminum alloy and stainless steel wire clamps have high mechanical strength, light weight, low installation costs, and transportation costs.

- Safety and environmental protection: Metal materials are easy to recycle and non-toxic, and will not pollute the environment.

- Sustainability: The cable clamps have a long service life, are strong and durable, and are easy to disassemble, so they can continue to be used after your project is completed. (For example, after completing your cable hanging project, you can continue fixing the house cables.)

Conclusion

After reading the above article, I believe you already know how to choose the best drop wire clamps. If you want to buy clamps of good quality, please contact us. We are a leading manufacturer and distributor of drop wire clamps in China. We can provide OEM and ODM product customization services according to your requirements.

Frequently asked questions

What are Drop Wire Clamps?

Drop wire clamps are used to connect and support cables on utility poles or buildings.

What types of drop wire clamps are there?

- Wire wrap type

- Compression type

What factors should be considered when choosing drop wire clamps?

- Application Areas

- Installation form

- Design Features

- Advantages

- Materials