Are you also worried about how to use eye nuts? Are their sizes, specifications, and specific methods of hoisting a headache for you? In the next article, I will help you to understand eyenuts and solve your troubles.

Table of Contents

ToggleWhat is an Eye Nut?

The eyenut consists of a cylindrical nut with an internal thread and a U-shaped ring. Because this ring structure looks like an eye, it is called an eye nut.

Eye nuts are commonly used in lifting or hoisting and are galvanized steel material connectors.

Types of Eye Nuts

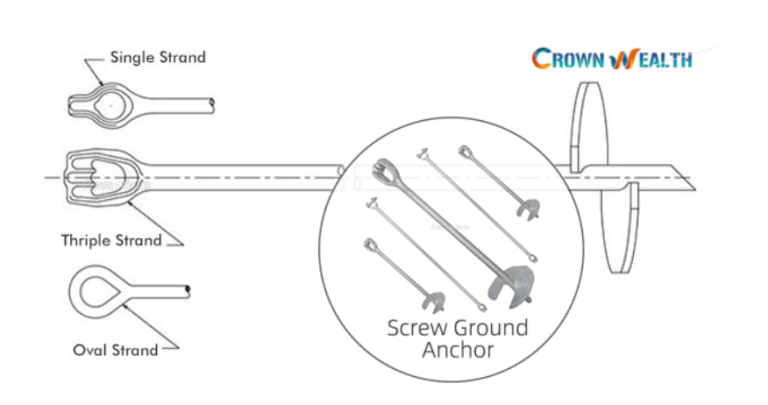

1. Single Forged Eye Nut

Usually used with double arming bolts, Machine bolts.

2. Type Oval Timble Eye Nut

Used for guy dead-ending from the threaded ends of electrical cross arm bolts.

3. Lifting Eye Nut Round Type

It is used for overhead power lines and pole line construction.

4. Timble Eye Nuts Long Type

5. Dual Forged Eye Nut

The dual forged eye nut is used for attaching to a thru bolt or thimble bolts for straight away head guys.

Where are eye nuts mainly used?

Lifting and Hoisting

Connect a sling or hook to the ring for lifting or moving objects.

Mechanical Engineering Connections

Eye nuts provide attachment points for mechanical components and fix those components. Using eyenuts can speed up installation and removal.

Electrical field

Eye nuts are used to fix electrical cross arms, drop wire clamps, and other pole line hardware on utility poles. You can also use its ring structure as a connection point for guy wires to stabilize utility poles.

Home decoration field

Eyenuts can bear a certain amount of weight and can be used to fix household items in your house (such as ceiling fans, lamps, curtains, etc.). The objects fixed with thread structures are more solid and not easy to loosen.

Features of Eye Nuts

Thread Design – The thread design ensures that the eye nut is more firmly connected to other components.

Material – Made of galvanized steel, it is strong and durable.

Corrosion resistance – Made of the hot dip galvanizing process and high-strength materials, it has increased corrosion resistance and is suitable for wet environments.

Strong carrying capacity – It can withstand larger loads, meet your project requirements, and ensure safe operation.

Low price – Eye nuts are low-cost to produce and economically priced.

Easy to install – The eye nut has a simple structure and can be installed and removed using only a lever.

How Should You Use Eye Nuts When Lifting?

- When lifting objects, you need to judge and choose the eyenuts of appropriate specifications, models, and loads by the weight of the object.

- Before using eye nuts, it is necessary to carefully check their quality. Deformed or cracked nuts should be replaced immediately.

- You need to make sure the bolt that the nut is mounted on is perpendicular to the surface of the workpiece. Place the washer and tighten the eye nut until it fits perfectly against the support surface.

- Attach the rigging to the eye nut ring.

- Use slow lifting, fast lifting, and slow lowering to complete the lifting of objects.

Other Accessories for Use With Eye Nuts

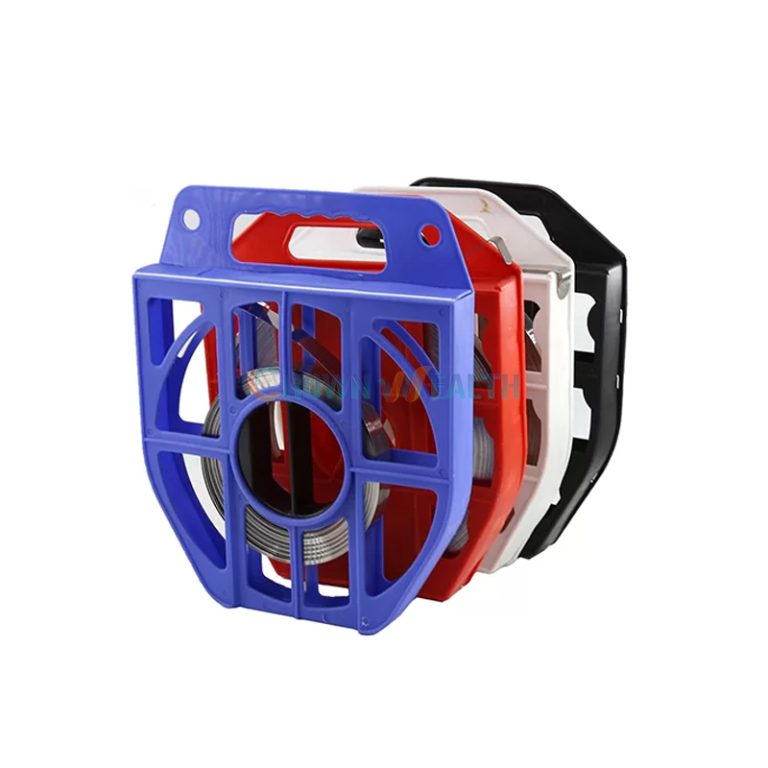

Eye bolts

It consists of a threaded bolt and a U-shaped ring, used in conjunction with an eye nut for lifting and hoisting objects.

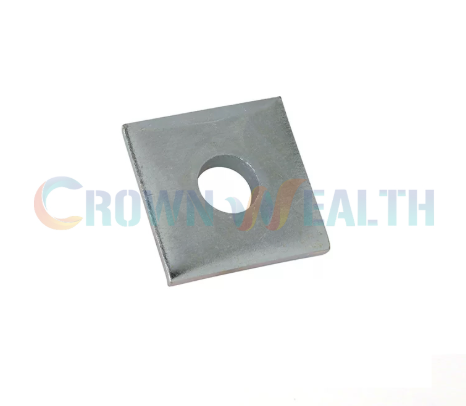

Square Washer

Used for the connection between eye nuts and eye bolts. Increase friction and make the fixation more secure

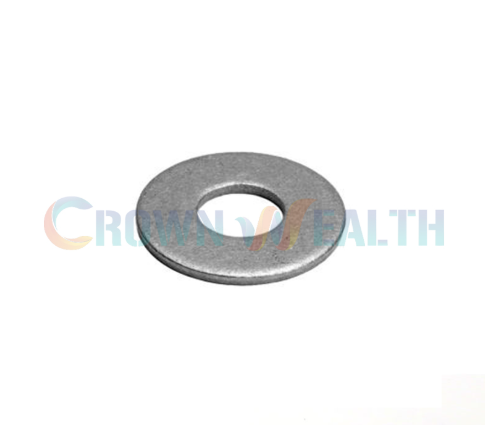

Round Washer

Used for spacers or supports under screw or bolt heads.

Eye Nut Manufacturers

Hebei Guankang is a leading eye nut manufacturer in China. We do OEM and ODM production according to your customization. Our eye nuts are made of galvanized steel and are plated using a hot-dip galvanizing process, resulting in high-quality products.

Frequently Asked Questions

What is an Eye Nut?

The eyenut is used for lifting or hoisting.

It is a galvanized steel material connector.

What are the Features of Eye Nuts?

- Thread Design

- Material

- Corrosion resistance

- Strong carrying capacity

- Low price

- Easy to install

What Other Accessories for Use With Eye Nuts?

- Eye bolts

- Square Washer

- Round Washer