Electric Pole Accessories

- Home

- Products

- Utility Pole

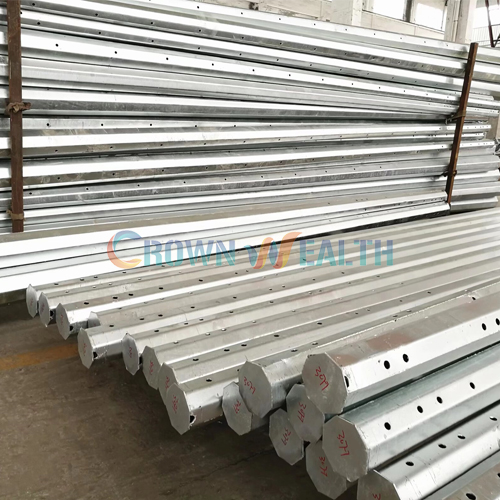

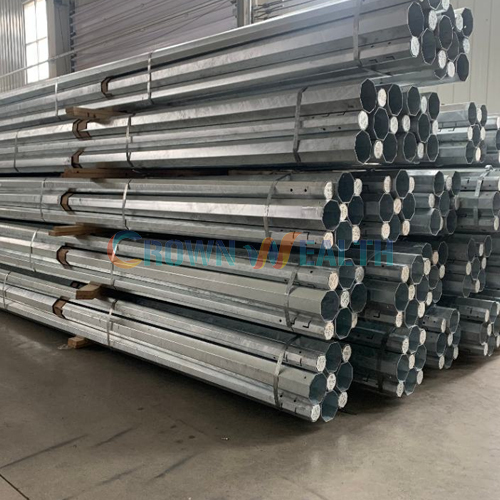

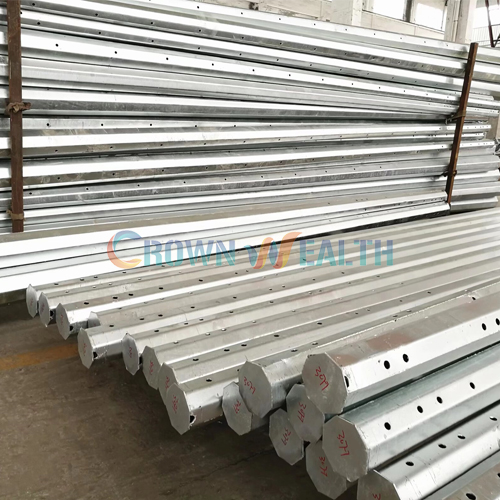

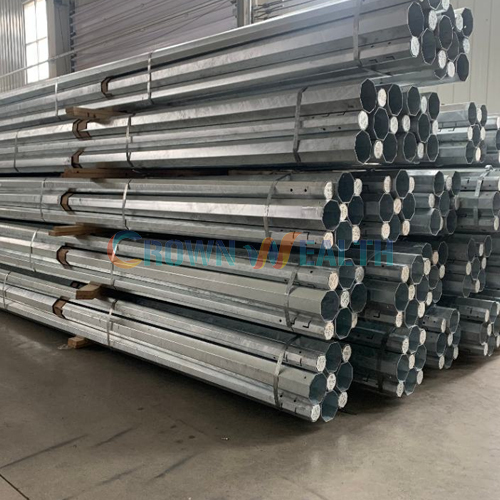

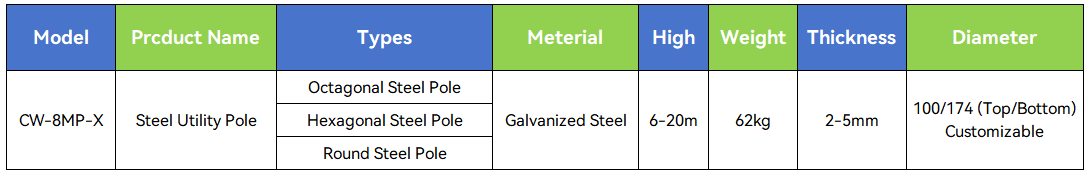

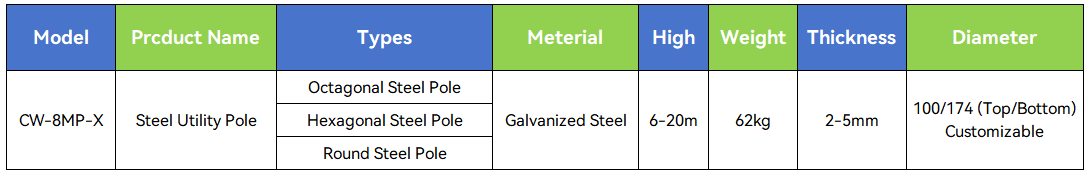

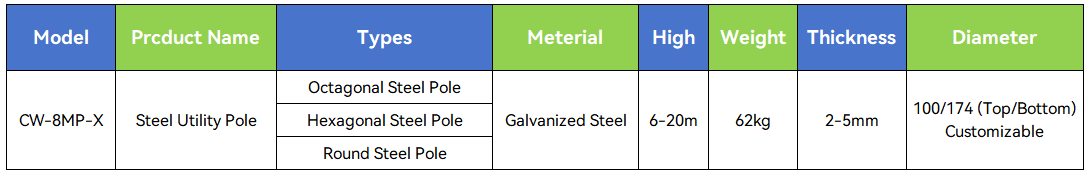

- CW-8MP-X: Steel Utility Pole | Octagonal Steel Pole | Galvanized Steel Utility Pole

Steel utility poles (also known as steel transmission poles, steel street light poles, steel telephone poles, steel power poles, and steel telecommunications poles) are used to support cables in the entire power transmission and communication transmission system. They are essential steel poles for supporting public facilities and service equipment.

Steel utility poles (also known as steel transmission poles, steel street light poles, steel telephone poles, steel power poles, and steel telecommunications poles) are used to support cables in the entire power transmission and communication transmission system. They are essential steel poles for supporting public facilities and service equipment.

There are three types of steel utility poles: octagonal steel pole, round steel poles and hexagonal steel pole.

We mainly wholesale octagonal poles, but we also sell the other two types of utility poles.

These galvanized steel utility poles are sturdy and durable, highly corrosion-resistant, and their grounding devices are designed to withstand higher voltage loads. They have an average lifespan of 60 years, require virtually no maintenance, and feature specially designed holes for easy installation.

Its service life is 40-60 years, depending on the installation environment.

Galvanized steel poles are more attractive and blend into the environment. They can be painted before installation to match the color scheme of city houses, and they are sturdy and durable.

Galvanized octagonal steel poles have low transportation and installation costs, with significantly lower costs compared to heavy concrete poles. Installation can be completed with just a small crane.

Galvanized steel poles enhance the aesthetics of a city, as their metallic outer layer blends harmoniously with the urban environment.

Steel poles completely prevent termite infestations, whereas wooden trunks require expensive termite protection, which is entirely unnecessary with steel poles. In areas with severe termite infestations, your galvanized steel poles will not become food for these destructive creatures.

The hot-dip galvanizing process involves immersing the utility pole in a zinc plating solution, forming a zinc-coated protective layer on the surface, which provides strong corrosion resistance.

Utility poles can be customized in size. We can manufacture octagonal, hexagonal, and round steel poles of different heights, thicknesses, and diameters according to your needs.

Hebei Crown Wealth, as a leading Octagonal steel pole manufacturer in China, boasts 15 years of experience in manufacturing, production, and export. We are dedicated to solving your cable transmission project problems. We possess advanced galvanized steel pole manufacturing technology and also produce various pole line hardware. With our own factory, you can communicate directly with the steel pole manufacturer, ensuring direct factory shipping and affordable prices. If you wish to purchase octagonal steel poles, hexagonal steel poles, or round steel poles, please contact us!

If you would like to learn more about utility poles, please read “The Complete Guide to Types of Utility Poles“

There are three types of steel utility poles: octagonal steel pole, round steel poles and hexagonal steel pole.

We mainly wholesale octagonal poles, but we also sell the other two types of utility poles.

These galvanized steel utility poles are sturdy and durable, highly corrosion-resistant, and their grounding devices are designed to withstand higher voltage loads. They have an average lifespan of 60 years, require virtually no maintenance, and feature specially designed holes for easy installation.

Its service life is 40-60 years, depending on the installation environment.

Galvanized steel poles are more attractive and blend into the environment. They can be painted before installation to match the color scheme of city houses, and they are sturdy and durable.

Galvanized octagonal steel poles have low transportation and installation costs, with significantly lower costs compared to heavy concrete poles. Installation can be completed with just a small crane.

Galvanized steel poles enhance the aesthetics of a city, as their metallic outer layer blends harmoniously with the urban environment.

Steel poles completely prevent termite infestations, whereas wooden trunks require expensive termite protection, which is entirely unnecessary with steel poles. In areas with severe termite infestations, your galvanized steel poles will not become food for these destructive creatures.

The hot-dip galvanizing process involves immersing the utility pole in a zinc plating solution, forming a zinc-coated protective layer on the surface, which provides strong corrosion resistance.

Utility poles can be customized in size. We can manufacture octagonal, hexagonal, and round steel poles of different heights, thicknesses, and diameters according to your needs.

Hebei Crown Wealth, as a leading Octagonal steel pole manufacturer in China, boasts 15 years of experience in manufacturing, production, and export. We are dedicated to solving your cable transmission project problems. We possess advanced galvanized steel pole manufacturing technology and also produce various pole line hardware. With our own factory, you can communicate directly with the steel pole manufacturer, ensuring direct factory shipping and affordable prices. If you wish to purchase octagonal steel poles, hexagonal steel poles, or round steel poles, please contact us!

If you would like to learn more about utility poles, please read “The Complete Guide to Types of Utility Poles“

Fiber Cable Clamp Manufacturer - Crown Wealth is proudly powered by WordPress

No.95 Qilian St. Shijiazhuang,China

info@hbcrownwealth.com

Phone: +86-311-89871588