Bolts and screws are key fasteners in our daily maintenance and industrial facilities. Bolts and screws can fasten together multiple parts made of multiple materials such as wood, metal, concrete and plastic to ensure the stability and integrity of the structure. From the appearance, bolts and screws are both threaded and have overlapping uses. What is the difference between bolts and screws? Below we summarize some explanations on how to distinguish bolts and screws from the perspective of design structure, use and installation, hoping to help you choose the right fasteners.

Table of Contents

ToggleWhat is the Difference Between Bolts and Screws?

Design and Structure

Appearance Design: Bolts have a head at one end and a cylindrical shaft that is non-tapered, with both smooth and threaded sections. The other end is flat and typically used with a nut. Most screws, on the other hand, are tapered and have threads along the entire shaft. Their tips are very sharp, allowing them to penetrate materials even without pre-drilled holes.

Structural Types: There are many styles and types of bolts and screws. The type of objects and components you are securing will determine whether you should use bolts or screws. Bolts are generally used with nuts to secure objects with holes in specified positions, such as anchor bolts for concrete, square head machine bolts for securing brackets through utility poles, and U bolts for fastening crossarms to utility poles. Common screws include wood screws, machine screws, and hex socket screws. Screw heads come in various shapes, including Phillips, slotted, and hex socket, making them ideal for being hidden within the objects you are securing. Hebei Crown Wealth offers screw-like hooks attachments, such as P House Hook, J Drive Hook, and Swing Hook, which are used to support aerial drop wire clamps, dead-end clamps, and service drops on utility poles and buildings.

Function and Usage

When you insert a bolt through a hole in an object, you thread a nut onto the threaded end of the bolt shaft, using a washer to apply strong pressure to secure the object in place. Bolts are ideal for applications that require disassembly and reassembly. You often encounter bolts in construction, machinery, and utility pole installations because bolts are the primary fasteners for connecting metal parts, securing machinery, and joining structural components.

In contrast, screws are directly driven into or joined with objects. Screws are widely used in woodworking, for installing hinges, and in construction for fastening various panels such as drywall. Screws can tightly fit into pre-cut threaded holes on the sides, while bolts cannot.

Installation and Tools

Bolts require pre-drilled holes and are used with nuts. You need a wrench or socket wrench to tighten them. Depending on the bolt head, you might need an open-end wrench, socket wrench, or power wrench. Screws, on the other hand, can usually be driven directly into your application without pre-drilling. However, pre-drilling can help avoid splitting the material, especially in harder woods. The tools needed depend on the screw head type, such as a screwdriver, a drill with the appropriate bit, or a power driver for increased efficiency.

Strength and Durability

Bolts are generally stronger than screws due to their design and the use of nuts to increase clamping force. The force is evenly distributed across the fastener and the material, allowing bolts to withstand higher loads, making them ideal for heavy-duty applications. Screws are typically used for medium or light-duty projects because they rely on their threads to grip the material. The strength a screw can handle depends on its size, material, and thread type.

In terms of durability, there is little difference between bolts and screws. Both are commonly made from materials like steel, stainless steel (in various grades), brass, bronze, and nylon plastic, with only slight differences in wear resistance. Screws are best suited for materials like plywood, metal sheets, drywall, particleboard, and decking boards. Bolts can support heavier loads, making them ideal for securing heavier materials such as concrete, metal, wood beams, or studs.

Common Types of Bolts Used in Electric Pole

Various bolts are needed in power and telecommunication lines to ensure the safety and stability of electric poles and infrastructure. Here are the common types of bolts used in electric pole installations:

Anchor Bolts: Provides foundational support, ensuring the pole remains upright and stable.

U Bolts: Used to attach the pole to supporting structures or to secure equipment and cables to the pole.

Oval Eye Bolt: Used for guiding and securing wires and cables on electric poles.

Thimble Eye Bolts: Used for attaching guy wires to poles, providing stability and support against lateral forces.

Square Head Bolts: Commonly used for attaching large components and for structural support, attaching components directly to wooden poles.

Hex Bolts: Commonly used for attaching hardware and equipment to the pole.

Carriage Bolts: Often used for securing wooden cross arms and other wooden components to poles.

Toggle Bolts: Used in situations where bolts need to pass through hollow structures, such as some pole designs.

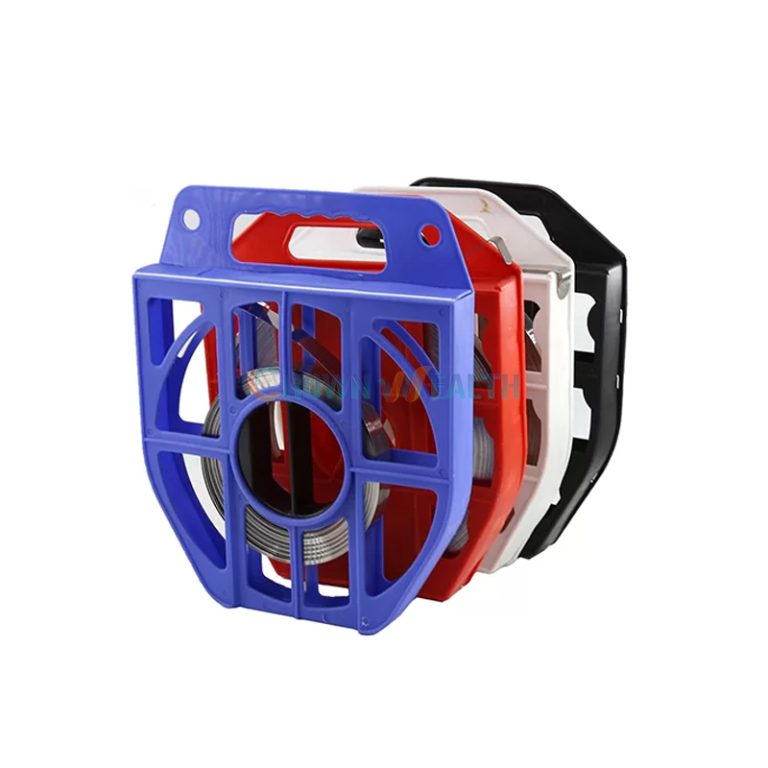

Hebei Crown Wealth is a professional Poleline bolts manufacturer and supplier. The bolts we provide are made of high-quality galvanized steel, hot-dip galvanizing meets ASTM F2329 specifications, materials meet ASTM A307 specifications, and sizes meet ASME B18.2.1 specifications. If you want to know more about bolts, please feel free to contact us.

Conclusion

In summary, knowing the difference between bolts and screws can ensure safe and stable operation of your project application. Bolts require nuts and pre-drilled holes, which provide strong clamping force and are suitable for heavy-duty applications. Screws provide convenience and ease of use, making them ideal for lighter tasks and direct engagement with materials. By choosing the right fasteners, you can ensure durability and effectiveness of your construction or repair work.

FAQ

What is a Bolt?

The bolt is a mechanical fastener with a rod with a threaded shaft and only part of the shaft is threaded. The bolt passes through all components with unthreaded holes, and then the nut is screwed onto the bolt to provide clamping force and prevent axial movement.

What is a Screw?

The screw head with a milled slot at one end, a fastener with threads on the outside of the shank. The tip is tapered and can be tightened or loosened by applying torque to the head with a tool, without the need for a pre-drilled hole.

How to Choosing the Right Bolts and Screws?

Before choosing bolts and screws, you need to understand the functional needs of your project, as well as the material and load requirements, which is important for choosing the right type of fastener. Then you need to determine the size of the bolt or screw to be used, such as length and diameter, and make sure you have the right installation tools. Also consider the use environment and cost, and choose the most cost-effective bolt or screw within the limited cost. By carefully evaluating these factors, you can ensure that the assembly is safe, stable and durable.