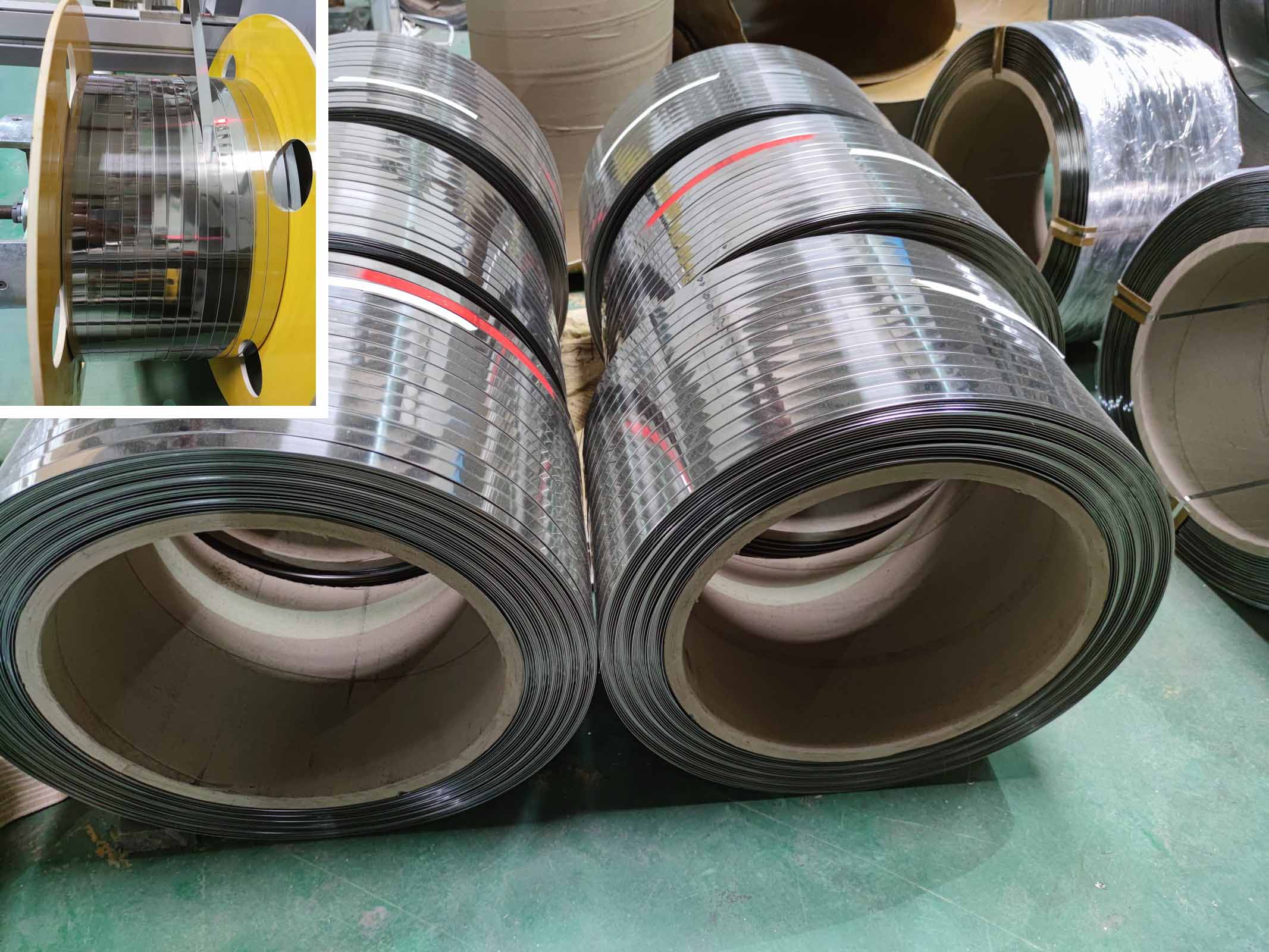

In power and other utility projects, equipment and cables need to operate stably and reliably in harsh environments, making stainless steel banding the best method for securing them. The corrosion resistance, high mechanical strength, and long service life of stainless steel banding solve these challenges.

Stainless steel banding is a type of cable tie used to secure pole and wire fittings to utility poles, and is widely used in network construction and electrical system fastening applications.

Table of Contents

ToggleFeatures

1.Excellent corrosion resistance: Stainless steel is made of elements such as chromium and nickel. When chromium is exposed to air, it reacts with oxygen to form a thin and stable chromium oxide passivation layer on the steel surface.

2.High tensile strength: Stainless steel bandings have very high tensile strength, which can fix heavy equipment or cables without easily breaking or loosening.

3.Excellent heat resistance: Made of high-strength metal, stainless steel strips can maintain their mechanical properties and integrity even in harsh environments.

4.Strong weather resistance and UV resistance: Stainless steel cable ties can withstand sun exposure and ultraviolet radiation, and their quality is far superior to that of plastic banding

5.Various sizes are available: stainless steel bands are available in a variety of sizes, allowing you to choose the appropriate length and width according to the size of your equipment to meet different application scenarios and needs.

6.Easy to use: The stainless steel strip can be installed by a single person. It can be tensioned, tightened, and cut quickly and efficiently using stainless steel strip tools.

Applications of stainless steel strips in utility projects such as telecommunications and power

1.Secure the communication cable to the utility pole:

Stainless steel banding reliably secures optical fibers and cables to utility poles. Its high tensile strength withstands the impact of wind and snow. It prevents cables from sagging or shifting.

2.Install the equipment casing:

Stainless steel strips are widely used to install fiber optic distribution boxes or transformer housings, securing them to utility poles.

3.Cable tray and conduit fixing:

In indoor or outdoor telecommunications projects, the use of stainless steel strapping is essential for securing cable trays or conduits. Its high strength and heavy-duty performance reduce the frequency and risk of maintenance.

4.Grounding system installation:

In public utility projects, grounding cables or grounding rods can be fixed to buildings, which is crucial for protecting equipment and people from electric shocks.

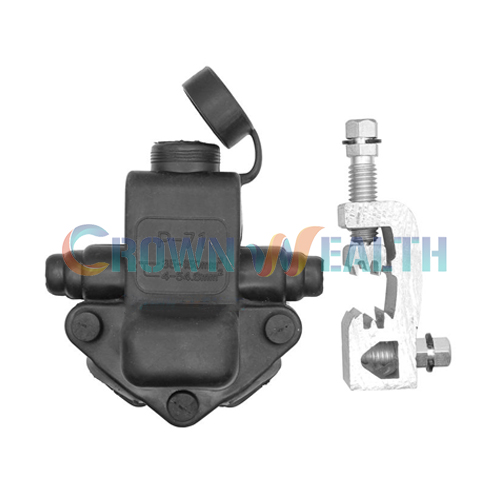

5.Fixed overhead line hardware

In power engineering, it is used to secure overhead line components (such as electrical insulators, tension clamps and drop wire clamps) to poles. Its resistance to ultraviolet radiation and harsh weather conditions prevents hardware from detaching, thus ensuring the reliability of transmission lines.

Why choose HB Crown Wealth as your stainless steel banding supplier?

Crown Wealth offers high-quality stainless steel strips with the following advantages:

- Meets international stainless steel strip material standards.

- The length, width, or thickness of each box of products are uniform, the quality is sufficient, and the size is standard.

- Stainless steel strip box stores stainless steel strips, and excess unused strips can be easily rolled up.

- The stainless steel strip edges are treated with a special process, so they won’t scratch your hands and arms.

- We offer customization and OEM/ODM services.

- Direct from the factory, large inventory, discounts for bulk orders.

Compared to other suppliers, HB Crown Wealth offers several competitive advantages, providing a one-stop solution for your stainless steel banding fixing problems. Contact us now!