Table of Contents

ToggleWhat is An Insulation Piercing Connector ( IPC Connector)?

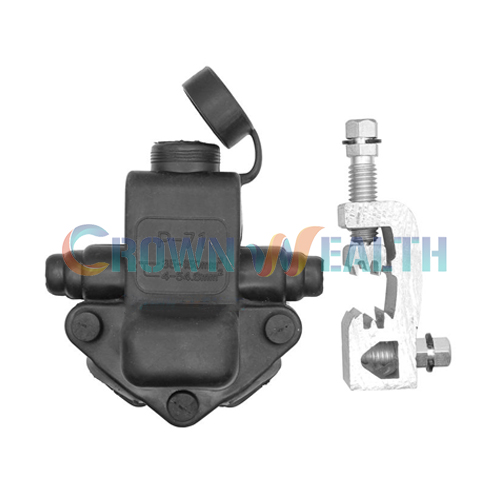

Insulation piercing connector also called IPC piercing connector, it is a power line hardware that allows wires to be connected without removing the insulation layer, and it is widely used in electrical power systems.

ICP piercing connector, as its name suggests, uses sharp metal teeth to penetrate the cable “armor,” contact the conductor, and form a strong, safe electrical connection. Its unique design allows for quick installation, used safely and efficiently, and avoids many of the risks associated with electrical connections.

The Structure of The IPC Connectors

1.Insulator main body

The connector insulator is made of high strength plastic, making it sturdy, durable, moisture proof, waterproof, and resistant to sun exposure and extreme cold, ensuring stable electrical power transmission.

- Materials: PP plastic or UV-resistant plastic.

- Applications: Used for insulation and environmental isolation.

2.Piercing metal teeth

The piercing metal teeth are a core component of IPC connectors. They are typically made of high-strength aluminum or copper and possess extremely high conductivity. Power is transmitted by tightening the connector to pierce the insulation layer and contact the wires.

- Materials: Copper or aluminum

- Application: To pierce insulation layers and make contact with wires.

- Design: The piercing design is safe and efficient, and does not damage the cable.

3.Bolts and clamping structures

Bolts and clamping structures are used to apply pressure during installation; they are typically made of stainless steel or galvanized steel and are robust and durable. Tightening the bolts causes the metal teeth to pierce the insulation layer, and fix the cable.

- Materials: Stainless steel or galvanized steel

- Applications: Applying pressure and securing cables

- Design: Bolts made of stainless steel or galvanized steel, with strong corrosion resistance and long service life.

4.Sealing components

Most IPC connectors have sealing gaskets or rubber pads. These components fit tightly against the cable surface at the connection point to prevent rainwater or air from corroding the wires, providing good sealing and waterproofing.

- Material: Rubber.

- Application: To prevent rainwater and air from corroding the wires.

- Design: Seal the puncture area to protect power transmission.

5.End caps

Some Insulation piercing connectors are equipped with end caps, which act as protective covers for the cable ends. They effectively prevent rainwater from entering the cable ends, protecting power transmission.

- Materials: Plastic or rubber.

- Application: To protect exposed cable ends from rain or dust.

- Design: Snap on design ensures power transmission.

6.Shear head bolts

To prevent over tightening from cutting the wires with metal teeth, IPC connectors typically use shear head bolts. These bolts automatically break off the head after reaching a certain pressure, ensuring even pressure distribution.

- Materials: Stainless steel or galvanized steel.

- Application: To prevent bolts from being overtightened and to ensure even pressure distribution.

- Design: The automatic breakage design reduces the risk of the wire being cut by the metal teeth, making it safe and efficient.

What are Insulation Piercing Connectors Used For?

Insulation piercing connectors (ICP connectors) are widely used in electrical and utility applications. Below, I will guide you through their specific uses.

1.Overhead power lines

IPC connectors are most commonly used in overhead power line systems, where cables are exposed to outdoor environments, where wind, sun, and rain can all affect power transmission. IPC connectors are designed for these environments, allowing for quick installation within the cable without stripping the insulation layer or exposing the wires.

- Application: Used for power transmission in overhead power grids.

- Advantages: Excellent waterproof and corrosion-resistant properties, suitable for overhead cable projects, eliminating the need for exposed cables.

2.Underground power lines

IPC connectors play a similar role in underground power distribution systems. When laying cables underground, it is also necessary to protect the integrity of the cable insulation. Damp soil can corrode cables, and sealing components protect the cables from corrosion and prevent short circuits.

- Application: Power transmission in underground power grids.

- Advantages: It isolates the underground power lines from damp soil, ensuring power transmission.

3.Street lighting systems

Insulation piercing connectors allow for branching of the cables required by a lighting system to individual streetlight poles. The metal teeth embed directly into the insulation layer, making the process simple and quick, and reducing labor costs associated with constructing street lighting infrastructure.

- Application: Connecting individual streetlights in urban and rural areas to the main power supply.

- Advantages: Easy to install, sturdy and durable.

4.Renewable energy systems

With the increasing prevalence of solar and wind power, IPC connectors play another important role: connecting cables in photovoltaic and wind power systems. Due to the harsh environments of these renewable energy systems, these IPC piercing connectors are the ideal choice. Their durability and corrosion resistance ensure more stable power transmission in renewable energy systems.

- Application: Connecting solar panels to the main power grid or other hardware.

- Advantages: It can operate stably in harsh environments and has strong durability and weather resistance.

5.Building power transmission

IPC connectors are commonly used for electrical connections in residential, commercial, and industrial buildings. They safely and efficiently branch mains power to other buildings without compromising cable integrity.

- Application: To distribute mains power to homes or businesses.

- Advantages: Easy to use and install, and improves the security of electrical transmission in residential and commercial settings.

6.Industrial applications

The insulation piercing connectors are used in large-scale industrial construction to connect large cables, enabling stable power distribution in factories and connecting to various machinery and equipment without interrupting processes.

- Application: To connect the main power supply to various machines and equipment.

- Advantages: Low cost, higher efficiency, making it the best choice for large-scale industrial power connections.

7.For temporary or emergency connections

In situations requiring rapid deployment of power systems, IPC connectors are the most efficient option, enabling the rapid establishment of reliable power networks.

- Application: To build a temporary power grid.

- Advantages: Rapid deployment makes them the preferred solution in emergency situations.

Advantages of Insulation Piercing Connectors

- Saves time – No need to peel off the insulation layer, installation is faster.

- High safety – IPC connectors reduce the risk of short circuits, electrical faults, and leakage.

- Highly durable – Operates stably in harsh environments, resistant to moisture, UV rays, and weathering.

- Low cost – Reducing installation and maintenance time, making it the best solution for various power transmission systems.

Conclusion

Choosing the right connector, whether it is an IPC or other type, is the best option for your power transmission. Learn about insulation piercing connectors to build safer and more efficient electrical systems. If you’re looking for high-quality IPC connectors, feel free to contact Crown Wealth for a quote. With 15 years of overseas export experience, we manufacture insulation piercing connectors in bulk and maintain a large inventory. Please contact us.