Table of Contents

ToggleWhat is stainless steel banding?

Stainless steel banding is also called stainless steel cable tie, It is a durable and corrosion-resistant banding tool. Its function is to fix some pole line hardware ( such as pole brackets, electrical cross arms, etc.) to the utility pole. It plays a key role in the construction of optical fiber networks and electrical transmission systems.

The main features of stainless steel banding

The main features of stainless steel bands are as follows:

Good corrosion resistance

Alloy elements such as Cr, Ni, and Mo form a passivation film that can remain stable in a humid and corrosive environment.

High mechanical strength

The tensile strength is ≥520 MPa, and it can withstand the impact of heavy rain, heavy snow and strong wind.

Durable and maintenance free

It is almost never rusted in normal atmospheric environments. It is 100% recyclable, has a long life cycle and extremely low maintenance costs.

Universal for multiple scenarios

Whether it is for home work, hanging and fixing objects, or in industrial-grade power environments, chemical grade marine environments, it can be perfectly fastened with minimal maintenance.

Competitive prices

As a leading stainless steel strip manufacturer in China, Hb Crown Wealth uses premium stainless steel raw materials. Our cold-rolled strips range in thickness from 0.03 – 3.0 mm, with tolerances of ± 0.005 mm. Widths range from 3 – 1250 mm, and can be stripped down to 2 mm narrow strips. We ensure precise blanking and neat coiling and provide OEM customization services, welcome your inquiries.

Related strapping products include

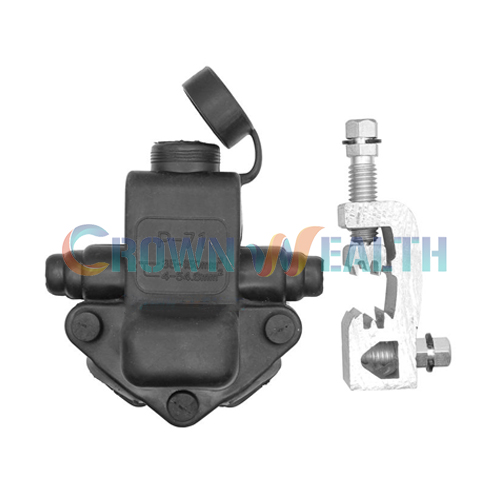

Stainless steel strapping tools

Application of stainless steel banding in power and fiber optic cable installation

Stainless steel cable ties are mainly used for fixing and organizing power and fiber optic cables. They are often used with pole supports and cable clamps to ensure the stability of cables even in harsh environments. Applications are as follows:

1.Key applications in power cable installation

Power cables are heavy and have high voltage, so the key to using stainless steel strapping is load-bearing and corrosion resistance.

Cable fixing on utility poles:Fix thick and medium power cables to poles, towers or crossarms to prevent damage to the cables due to wind and bad weather.

Bundle multiple power cords: Bundle parallel power cords together to reduce vibration and avoid friction between cables, making your electrical project more neat and organized.

Fixing accessories: Fasten the pole hardware bracket to the utility pole to ensure it is fixed in place and maintain stable power transmission.

2.Key applications in optical cable installation

Fiber optic cables can be fixed to the inner wall of underground or overhead pipes to prevent bending.

Support in Passive Optical Networks (PON): In outdoor PON installations, tie wraps are used to secure fiber optic distribution boxes or drop cables to avoid stress on the cables.

At the fiber termination point, fix the fiber pigtail or jumper to keep the area clean.

3.General Installation Steps

Use the stainless steel strapping tool to cut the stainless steel strapping to your desired length

Wrap the straps around the cables and support structure, ensuring they are aligned.

Use the tensioning tool to tighten the strap, secure it in place with the stainless steel buckle and trim the rest of the banding.

Regular inspections: Check that the binding is secure, the cable is not deformed, and the buckles are firmly fixed to ensure long term reliability.

For more information, please contact us and our team will assist you in selecting the best stainless steel belt products for your grating network project.