Perforated steel banding, also called perforated steel strapping, perforated metal strapping and multi holes perforated band.

This type of hardware is widely used in fields such as construction, power, and communications. In this guide, I will provide a comprehensive overview of everything you need to know about perforated steel strips.

Table of Contents

ToggleHow are perforated steel banding made?

The perforated banding is made from a strip of steel through a punching process. A punch and a die are used to evenly punch holes of the appropriate size into the pre-formed stainless steel band.

The size and spacing of the holes are customizable to suit your needs. Smaller holes offer good flexibility, while larger holes provide greater strength. Standard hole diameters range from 0.1 inches to 0.5 inches.

After perforation, the steel perforated strip may require degreasing, galvanizing, and other processes to improve its corrosion resistance. Finally, it is presented to you in boxed rolls for easy transport and use.

The main advantages of perforated steel banding

Perforated steel strip has many advantages, which are introduced below:

1.Flexibility

Perforated steel bandings are more flexible, can be easily bent and deformed without cracking or breaking, and can fix objects more tightly.

2.Ventilation

The perforated design facilitates heat release and air circulation, making perforated steel bandings an excellent choice for securing items that require ventilation in packaging boxes.

3.Lightweight and high tensile strength

Perforated steel strips are not only lightweight but also possess excellent tensile strength, making them suitable for binding and securing items. The holes not only reduce the weight of the material used and minimize material waste but also make the perforated stainless steel strips more durable.

4.Customizable

Perforated banding can be customized to different hole diameters, spacings, and widths according to your requirements. The galvanized coating effectively prevents corrosion.

5.Economical and affordable

Perforated banding boasts high strength and excellent breathability. Compared to solid steel tape, the perforated design reduces material usage and manufacturing costs. The box design further minimizes packaging and transportation costs, making perforated strapping stand out in numerous projects.

Application of perforated steel banding

Perforated bandings have a wide range of applications.

Construction industry

- Fixed reinforcing bars or reinforcing steel frame

- Fixed electrical wires, ventilation ducts, drainage pipes

- External wall panel fixing

Package

- Bundled boxes, crates, wooden crates

- Bundling express parcels

Industrial use

- Stainless steel perforated strips can be fixed to walls to hold shelf parts, tools, and materials.

- Fixed factory signs or notices

- Fix pipes and equipment

- Fixed optical cables, electrical cables

Process

- Used as a decorative item

- Bundling dried flowers or spices

Agriculture

- Support and fix crops

- The perforated banding can be used to secure bird spikes and bird nets.

- Bundling hay, animals chatting privately

Types of perforated steel banding

Based on their usage, characteristics, and form, perforated bandings are classified into several categories.

Flat perforated bandings are also called galvanized steel strapping with holes. They retain the shape of the original steel coil, and the uniform perforations make them easier to bundle and connect, and can be easily fixed to objects such as cylinders or pipes.

The wavy band has a serrated shape, good flexibility, strong grip, and high friction. It securely holds items in place.

Twisted bands are made by twisting flat perforated bands at a certain angle. Offering excellent flexibility and conformability. Furthermore, they possess strong gripping power, making them suitable for securing cylindrical objects.

Coatings and accessories

Coating

Bare steel – Perforated steel sheet without any coating, prone to corrosion.

Galvanizing – A process called hot-dip galvanizing is used to form a zinc layer on the surface of steel to enhance its corrosion resistance. It is the most common surface treatment.

Painting – Paint can prevent corrosion and also provide an aesthetically pleasing finish to the perforated tape.

Plastisol – It is a plasticized coating for polyvinyl chloride (PVC) that exhibits extremely high corrosion and chemical resistance. It is commonly used in harsh environments such as acidic, alkaline, and salt spray conditions.

Accessories

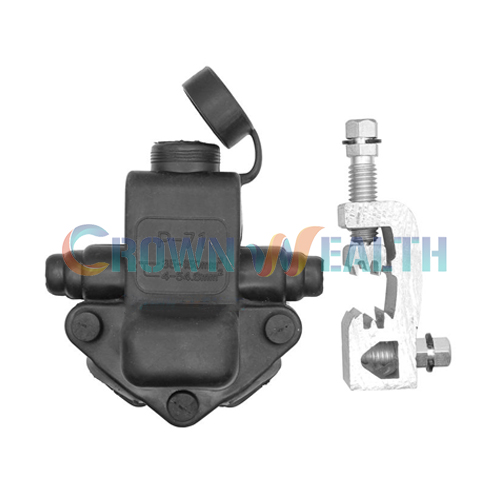

Stainless steel buckle – Used to tighten and secure straps, common types of buckles include L type buckles, ear teeth type buckles, and universal strapping buckle.

Seals – Crimped metal seals can hold the ends of the belt together for permanent fixation.

Banding tools – Tensioners/bundling tools can be used to tension and cut strapping tape. They can be operated by a single person, are highly efficient, and are safe.

How to choose the right perforation banding?

There are many types of perforated tape, and choosing the right perforated tape is crucial for your project.

Application Scenarios – Choose based on the intended use of the perforation tape, such as light binding, heavy-duty fastening, or decorative applications. This will help you make the selection.

Size – Choose the appropriate perforation banding based on the dimensions (length, width, and thickness) of the items being bundled.

Strength – Select the appropriate strength of the perforated tape based on the item being secured. For items with higher tensile strength, choose tape with higher tensile strength.

Environment – If exposed to moisture, acid, chemicals, or UV radiation, use a galvanized coating, paint, or perforated tape with high corrosion resistance.

Budget – If you have a limited budget, choose a perforated banding with a larger aperture or thinner steel thickness. If you have a higher budget, choose a stainless steel perforated banding with a smaller aperture and thicker steel thickness.

How to use perforated banding safely?

- Wear sturdy gloves when handling or using to avoid cuts from the sharp straps.

- When cutting the strap using a stainless steel strap tool, be aware of the springback of the perforated end of the strap.

- Tighten the perforation banding appropriately, but do not overtighten it.

- Use stainless steel buckles and seals correctly to prevent them from falling off.

- Handle with care to avoid damaging the coating.

Perforated steel banding vs. solid steel banding

Compared to solid steel strapping, perforated strapping is weaker and more suitable for light-duty securing and binding projects, while solid steel strapping is better suited for heavy-duty binding projects. Solid steel strapping is more expensive, heavier, and requires more materials, and it lacks ventilation. Perforated strapping is less expensive and breathable. Choose the appropriate strapping based on specific application requirements.

Conclusion

Perforated steel strapping has gradually become an indispensable accessory in many industries due to its advantages such as good air permeability, high flexibility, and low cost. If you want to buy high-quality and affordable perforated strapping, HB Crown Wealth is your best choice. Mechanized automated production ensures uniform texture, superior quality, and affordable prices. Customization services are available, providing a one-stop solution for your perforated strapping problems. Welcome to inquire!