It is undeniable that your power transmission lines and signal transmission lines need electrical cross arms.

In this guide, I’ll show you how to choose the right electrical cross arm.

Understanding their technology, specifications, usage scenarios, shapes, etc. can make your purchase more efficient.

The good news is that you can find the answer in this guide.

What is an Electrical Cross Arm?

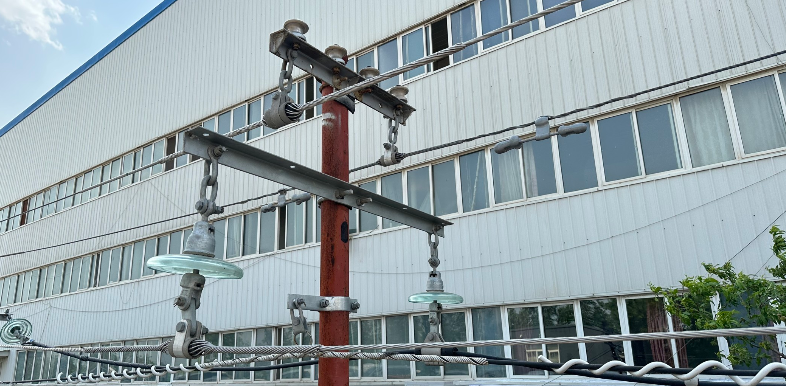

It is the connecting bridge between the utility pole and the pole line hardware, and is an indispensable pole line equipment in power transmission and signal transmission projects.

To meet the demands of power distribution and transmission, you need to choose a strong and durable cross arm with the best performance and design.

Electrical cross arms are also called telephone pole cross arms, lamp pole crossarms, public facility cross arms, power pole cross arms or simply cross arms. As the name suggests, cross arms with different names have different usage scenarios.

For example:

Electrical cross arms are connected to insulators via insulator pins, which are then connected to conductors to transmit power.

Hang the tension clamp through the round hole of the power cross arm, then use the cable clamp to hang the fiber optic cable.

Light pole cross arms are used on light poles to provide power to street lights.

Why do Transmission and Distribution Lines Need Electrical Cross Arms?

Electrical cross arms perform different functions depending on the application scenario.

They are essential infrastructure for railways, power companies, telephone companies, road administration, and signal transmission companies.

These cross arms must provide a sturdy and durable platform for harsh outdoor environments, ensuring stable power transmission.

On light poles, the electrical cross arm provides support for the power cables of streetlights.

Electrical cross arms, along with stainless steel cable ties, cable clamps, and tension clamps, are used to support and secure cables.

They secure the cables and insulators to the main structure, typically the pole or pylon.

During electrical transmission, the uniform spacing of the holes on the cross arm ensures adequate space for the wiring.

Manufacturing Process of Electrical Cross Arm

The manufacturing process of electrical cross arms depends on the type of material used.

The following techniques are required to fabricate the steel cross arms. Remember to follow all safety guidelines.

Cut according to your drawing or required size and drill holes as required. Then, use the hot dip galvanizing process to provide a dense protective layer for the steel cross arm,increasing their corrosion resistance.

How to purchase the required electrical cross arms?

1.Material

Most companies prefer to use galvanized steel to make cross arms. Compared with wooden cross arms, wooden cross arms have poorer durability and service life. Bad weather, humid air, and strong winds may corrode and destroy wooden cross arms.

So, that’s why the material has to be durable, mechanically strong, and corrosion resistant.

2.Shape Design

The most common shape of an electrical cross arm is rectangular. Their straight design makes them a common sight on utility poles.

They are simple to manufacture and install, making them one of the most popular types of electrical cross arms.

Another shape of cross arm we can also see on power lines is the T-shaped crossarm which provides additional support on the pole, with multiple holes providing ample space to connect multiple conductors and insulators.

3.Holes

The holes on the electrical cross arms are used to connect various components. The holes are sized appropriately based on the size of the components. The cross arm accessories must be securely fastened and fixed in place, so the holes must be the correct size. Different numbers of holes connect different numbers of cables.

4. Bolts and Nuts

Bolts and nuts secure the pole line hardware to the cross arms and the cross arms to the poles. Different fastening devices are used depending on the specific situation.

Main types include: pigtail bolts, U-bolts, stainless steel cable ties, etc.

5. Hot Dip Galvanizing Process

Hot-dip galvanizing is the final process for steel electrical cross arms, giving them corrosion resistance. This will greatly increase the service life of the electrical cross arms and avoid excessive replacement and maintenance.

6. Weight

The weight of an electrical cross arm depends on the type of material it is made of and the environment it will be used in. Typically, the weight of the materials used varies, thus affecting the overall weight of the cross arm.

7. Tensile strength

Electrical cross arms often operate in extremely dangerous connections for extended periods of time.

Therefore, the cross arms tensile strength must be very high to withstand these harsh conditions. Furthermore, the tensile forces of the connections are often applied to the cross arm, making it extremely sturdy. Review the materials and connection types used in the cross arm. Whenever possible, use high-quality materials to avoid issues related to weight or quality.

Installation Process of Electrical Cross Arm

The installation of electrical cross arms is relatively simple, but requires professional personnel to complete.

Please exercise caution and wear protective gear.

Prepare the required pole hardware, crossarms, and fasteners based on your installation method.

(If you’re using a wooden pole) Drill holes in the pole and secure all relevant components (such as conductors, insulators, and clamps) to the crossarms. Then, use a power lift to bolt the crossarms to the pole.

(If you are using a steel pole) Fix all the relevant parts to the cross arm, and then pass the stainless steel tie through the hole of the cross arm. Then use the stainless steel buckle and stainless steel tie tool to fix the cross arm to the pole with the help of a hoist.

Frequently Asked Questions

What is an electrical cross arm?

The electrical crossarm is a supporting device, also known as the electric pole crossarm, lamp pole crossarm, and power pole crossarm.

What types of electrical cross arms?

- Top Crosshead Electrical Cross Arm

- Galvanized Short Cross Arm

- Square Tube Extension for Pole

- Cross Arm With 11 Holes

- Powder Coated Electrical Cross Arm

- Electrical Cross Arm

- Multiple Drop Wire Cross Arm Brackets

- Platen Electrical Cross Arm

How to select the electrical cross arm?

- Material

- Shape Design

- Holes

- Bolts and Nuts

- Hot Dip Galvanizing Process

- Weight

- Tensile strength

Conclusion

In line support, electrical cross arms must be robust enough to withstand harsh environments.

Hb Crown Wealth, a leading expert in the design and manufacture of electrical cross arms in China, has its own factory and technical experts. We offer factory direct sales and OEM services to help you select the best cross arms.