In today’s world, where power and communication networks are rapidly upgrading, drop wire clamps play a vital role in securing optical fiber cables and protecting line safety.

Hebei Crown Wealth Metal Products Co., Ltd., located in Shijiazhuang, Hebei, China, is a leading manufacturer of drop wire clamps.

Since its establishment in 2011, the company has been dedicated to the research, development, production, and export of drop cable clamps, aiming to become a leading overhead line hardware manufacturer based in Asia.

Digital workshop and 8,000㎡ factory. It has strong production capacity

Dozens of injection molding machines and stamping robots work alternately, with real-time monitoring from raw material arrival to finished product packaging, ensuring high-quality, defect-free products. Multiple production lines and over 100 sets of precision molds guarantee on-time or even early delivery of your orders.

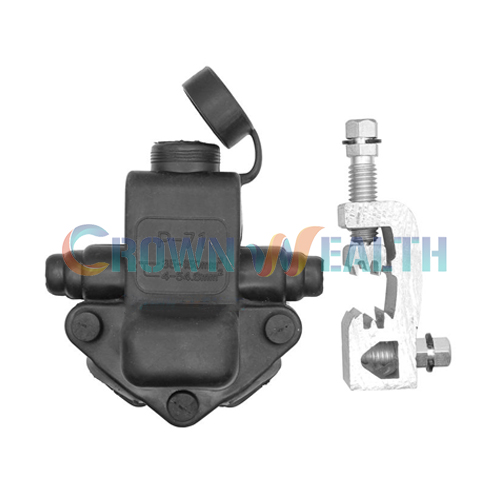

There are many types of drop wire clamps

1.Plastic drop wire clamp with S hook:

It is made of UV-resistant reinforced plastic and features a stainless steel S-hook. It has passed a 1000-hour salt spray test without cracking and is designed specifically for FTTH cables.

2.Stainless steel wedge drop wire clamp:

It is made of 304/316 stainless steel, with extremely high mechanical strength and strong corrosion resistance. With a tensile strength ≥ 600 N, it is suitable for highly corrosive coastal environments. The all-metal construction and gaskets ensure your cables and wiring remain undamaged and operate stably.

3.Aluminum alloy drop wire clamp:

These aluminum alloy drop cable clamps ensure tensile strength while prioritizing customer cost-effectiveness, offering high performance at an affordable price. They are suitable for 220 kV overhead ground wires.

4.One-piece injection molded plastic drop wire clamp:

It adopts a one-piece injection molding tail fin, which enhances tensile strength while reducing wind vibration. Suitable for high-altitude and windy applications, it offers excellent insulation.

Experimental-level quality control

While manufacturing our products, we also maintain strict quality control. From raw material intake to product manufacturing and final product delivery, professional engineers conduct random sampling inspections at every stage.

We also have our own product testing laboratory, capable of performing salt spray tests, anti-aging tests, tensile tests, and other tests on drop wire clamps, providing international reports to ensure stable operation and low maintenance of your lines.

Tensile strength test: 0 → 1200 N uniform loading, hold for 1 min without slippage;

Salt spray test: 5% NaCl, 35℃ continuous spraying for 1000 h, red rust area of coating < 5%;

UV aging: UV-B 313 fluorescent tube for 500 h, color difference ΔE ≤ 1.5, impact strength retention ≥ 90%.

Validated in 50+ countries worldwide

From a 7,000 km FTTH trunk line in Mexico to a 500 kV dual-circuit ground wire in Chile, Crown Wealth drop wire clamp has been operating stably for over 5 years under various extreme conditions such as high salt spray, high ultraviolet radiation, and high altitude, with a customer return rate of less than 0.02%.

OEM/ODM

We offer customization services, able to tailor drop wire clamp hardware to your specific needs (wire diameter, span, material, tensile strength, galvanizing, powder coating, etc.). We can also meet your personalized requirements for laser-engraved logos, cartons, etc.

Conclusion

Advanced R&D, production, strict quality control, and high production efficiency are key factors that set us apart from other factories in China. If you are looking to purchase drop wire clamps for your project or if you wish to buy in bulk, please contact us.