Plastic cable tie clips are lightweight fasteners widely used in Fiber-to-the-Home (FTTH) applications, for securing cables, distributing cable tension, and suspending cables. They are typically injection-molded from weather-resistant engineering plastics (such as PA, PP, and ABS), offering advantages such as insulation, corrosion resistance, and light weight.

I will systematically summarize the product information for you from the following aspects and provide purchasing recommendations.

Table of Contents

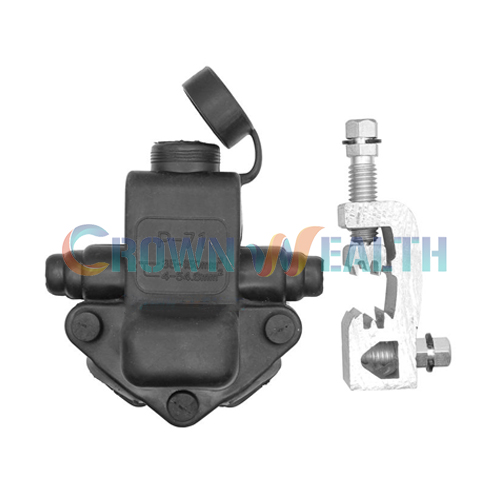

ToggleWhat is The Plastic Fiber Optical Wire Clamp With S Hook?

Plastic cable clamps (also known as “cable clips,” “drop clamps,” or “anchoring clamps”) are primarily used in communication, power, and other applications for the temporary or permanent securing and tension distribution of fiber optic cables, electrical cables, or steel wire ropes.

The plastic cable clamp with S hook is a one piece, injection molded cable clamp with an S shaped hook at the top made of galvanized steel or stainless steel 201 and the rest of the body and wedges are made of plastic. Snapping onto cables with a diameter of 3–12 mm. The S hook can be quickly attached to electrical cross arms, pole bands, or house brackets. Common materials include UV-resistant nylon, which are strong and chemically resistant, with an operating temperature range of –30°C to +60°C.

The plastic clamp structure consists of three parts:

Housing (body): One-piece UV-resistant plastic, providing mechanical strength and resilience;

Pull ring: Stainless steel or galvanized pull ring, for connection to steel strands, hooks, or clamps;

Wedge: Self-adjusting wedge that securely grips the cable according to its diameter, preventing slippage.

Core Advantages

- Lightweight: The density is only 1/5 of that of metal, significantly reducing the burden during high-altitude or pole-mounted operations;

- Insulating: Volume resistivity >10¹⁴ Ω·cm, allowing for live-line work and preventing short circuits;

- Easy Installation: No screws or cable ties are needed; installation is completed simply by inserting the wedge block, saving time and effort;

- No Surface Damage: The plastic casing will not scratch paint or wear down cable insulation like metal clips;

- Weather Resistant: Carbon black-added PA66 can operate long-term at -40℃~+85℃, resistant to UV radiation, salt spray, and acids and alkalis;

- Vibration Damping: The high damping of the plastic reduces fatigue damage to fiber optic cables caused by wind vibration;

- Non-magnetic: Suitable for EMI-sensitive environments such as hospitals, laboratories, and data centers;

- Flame Retardant: UL94 V-2 rated, self-extinguishing after removal from flame, improving safety on outdoor pole lines;

- Reusable: The removable wedge can be opened and closed hundreds of times without failure;

- Easy Color Matching: Distinctive colors such as black and blue can be achieved without secondary painting, facilitating maintenance and identification.

How to Install The Plastic Wire Clamp With S Hook?

Application Scenarios:

FTTH Communication: For the last-mile connection, a Φ2–6 mm round or flat drop fiber optic cable is secured to utility poles, walls, or corners using plastic wire clamps, allowing for spans of 50–80 meters;

Low-voltage power: Used for 0.6/1 kV bundled cables, suspended and anchored on poles for lighting lines, replacing metal drop wire clamps, reducing the risk of electrical leakage and lowering costs;

Temporary power and communication line setup: The wedge-shaped blocks can be repeatedly opened and closed, allowing for the rapid deployment of emergency power and communication systems;

Photovoltaic cable DC wiring: Clamp the micro inverter lead wires to the component frame. The plastic wire clamp can eliminate the risk of line current series connection.

Charging pile transformation: When threading the charging station cable, use S-hook plastic cable clips to hang it below the rafters, instead of insulating J-hooks.

Problem Description and Solution

- Ultraviolet light causes powdering of cable clamps – Choose black, UV-resistant plastic. Replace every three years for rooftop photovoltaic installations or locations exposed to direct sunlight.

- Low-temperature creep – For static loads >5 kg below –10°C, derate to 2.5 kg, or use a plastic wire clamp with fiberglass.

Summary

For low-voltage, temporary power supply applications where weight, corrosion, or accidental grounding are a concern, plastic cable clamps with S-hooks are a code-compliant, cost-effective upgrade that speeds construction and improves safety.

Why Choose Hebei Crown Wealth?

As a leading Chinese manufacturer of S-hook plastic drop wire clamps, we have 15 years of experience in production and export. We offer OEM/ODM services and can customize colors and packaging. We sell directly from the factory at competitive prices. Although seemingly small components, plastic wire clamps play a crucial role in various fields, including telecommunications and power distribution. Choosing a high-quality, weather-resistant, and reliable supplier is key to ensuring the lifespan of your projects and minimizing maintenance costs. If you are interested in purchasing our products, please contact us!