Table of Contents

ToggleShapes of Span Clamps – Ultimate Guide

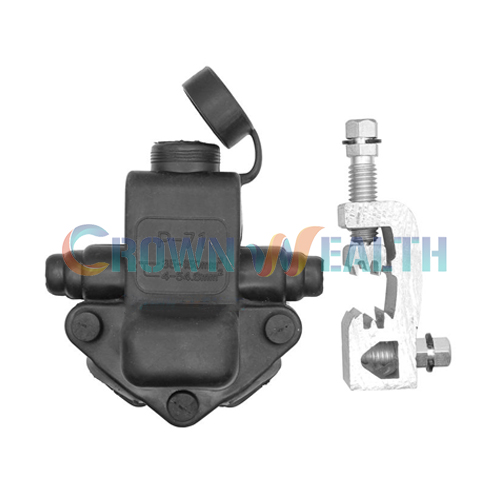

In pole line hardware, Span clamps have a variety of shapes.Used to fix and support cables.

Today, I will take you to explore the shape characteristics of span clamps, as well as their materials and uses.

Shapes of Span Clamps

D cable lashing clamp is a common span clam in daily life, It is main body is D-shaped, which can better fit the circular cross section of the cable. It is small in size, does not take up space, and is easy to install. You can place the cable into the groove of the span clamp and then tighten the screws, and fix the cable is finish.

E type lashing wire clamp made of high-strength aluminum jaws and a specially shaped bolt and square nut.The bend of its jaws is integrated, which can better fix cable.The material of galvanized steel and aluminum alloy enhances its corrosion resistance and can withstand decades of corrosive environment.

Z type clamp is suitable for thinner electrical or optical cables. The Z-shaped design can adapt to high-intensity impact and has a certain degree of stability.Hot-dip galvanizing is used to improve the corrosion resistance and life of the span clamp.

The shape of the C span clamp is the letter C. This structure has good stability, and the C-shaped hook at the tail can withstand strong pulling forces.The span clamp has adjustable bolts and nuts that can better fit the circular cross section of the cable and different diameters.Its inner surface has anti-slip texture, which can effectively prevent the wire from sliding in the fixture.

As the name suggests, its bolt is shaped like the letter Q and is used to hang the cable, and the Q span clamp can also be adjusted to accommodate cables of different diameters.

The double opening design of the O span clamp allows for better cable installation, and the galvanized steel material makes it more corrosion-resistant, making it one of the fastest span clamps to install.

Material of Span Clamp

Galvanized steel:

Galvanized steel span clamps have good metal strength and tension. Hot dip galvanizing process can effectively prevent steel corrosion and adapt to humid and salt spray environments.

Aluminum Alloy:

The span clamp made of aluminum alloy has good corrosion resistance. A dense aluminum oxide film will form on its surface, which effectively isolates the humid water vapor in the air from the equipment. It is also suitable for humid and salt spray environments.

FAQ

Does shape affect the performance of span clamps?

The shape is important for span clamps performance, reasonable shape can improve the stability and corrosion resistance of the span clamp and make it easier to install.

Where can I buy the best span clamp?

Hebei Crownwealth is a developer and distributor of span clamps. If you want to learn about and purchase span clamps, please contact us.

If you want to learn about some special types of fiber cable clamps, please click here.

What are the application scenarios for the use of span clamps?

Power Industry: Used for mid span drop wire hang.

Communications Industry:Used to protect fiber optic cables and support antennas.

Construction Industry:Used to fix some smaller drainage pipes or cable trays.

Transportation Industry:For fixing traffic signal lines.

What are the key points for maintaining span clamps?

- Check the appearance of the Span Clamp regularly to see if there is any sign of deformation or damage.

- Check the connection between the fixture and the wire for wear or deformation.

- Check if the bolts and nuts are loose, if so you can retighten them.